- Largest engineering company in Saxony for the past 30 years

- Today’s portfolio: from sheetfed offset to inkjet packaging printing, die-cutting and folding carton gluing – and now digital print

- Festivities for the employees on 29 September

On 29 September, Koenig & Bauer celebrated the 125th anniversary of its location in Radebeul near Dresden.

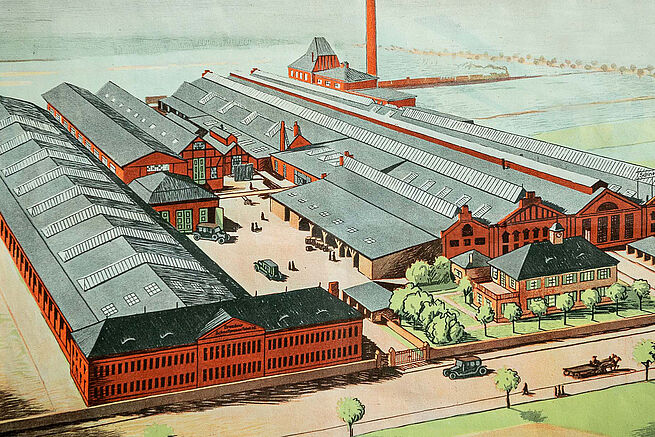

With its 1,800 employees, the factory is today considered the largest engineering company in Saxony. It is the modern-day successor to Dresdner Schnellpressenfabrik, the company founded on Blasewitzer Straße in Dresden in 1898 by Joseph Hauss and Alfred Sparbert. It relocated to Brockwitz just two years later before moving premises again in 1911, namely to Radebeul-Naundorf, where the company still has its offices today.

Innovative solutions for the print industry

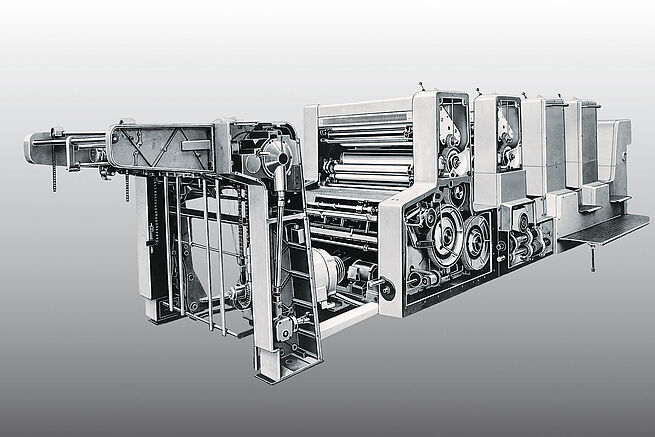

The company caught the attention of the world market from the very beginning. The first in a stream of innovative solutions was a ‘fixture for moving the printing foundation of high-speed printing presses’, the planetary drive, which lent its name to decades of press models and was adopted as the name for the whole company from 1938. In 1932, Planeta produced the world’s first four-colour sheetfed offset press. Another world first designed in Radebeul was a unit-based sheetfed offset press unveiled in 1965. This design principle has since become the accepted norm and has remained the industry standard to this day.

More recent developments with which Koenig & Bauer continues to set international benchmarks in sheetfed offset include automation solutions such as the sidelay-free infeed DriveTronic SIS, fully automatic plate logistics and a variety of digitalisation options. Rapida sheetfed offset presses today deliver an unrivalled performance in many format classes and are also makeready world champions.

There were, unavoidably, also a few lows and darker periods to be endured over the course of 125 years of manufacturing at the location. These included two world wars, hyperinflation and currency reforms, the planned economy of the GDR years, subsequent restructuring for a market economy and the catastrophic Elbe floods of 2002. Time and again, however, the employees stood by their company – with passionate commitment, consummate skill and countless good ideas for ways to advance the fortunes of the press engineering.

Complete solutions for packaging and folding carton production

Today, the Koenig & Bauer factory in Radebeul represents much more than just the group’s value centre for classic sheetfed offset. It also bundles all group activities relating to an integrated packaging production workflow. The current product portfolio in Radebeul includes rotary die-cutters based on the offset press platform. Flat-bed die-cutters are supplied by subsidiary Koenig & Bauer Iberica in Barcelona. Added to this are the folder-gluers contributed by Koenig & Bauer Duran in Istanbul. In this way, products from Koenig & Bauer cover the entire process chain of folding carton production.

Alongside sheetfed offset presses, Radebeul design engineers working within the framework of a joint venture with the company Durst have developed the VariJET 106, a digital printing press that combines the strengths of inkjet with the benefits of an offset process. By bringing together important elements of the two processes, the new press raises packaging printing to the next level and enables the production of innovative, future-oriented packaging solutions. The first presses in this series were put into operation by users over the past few months.

Strong player far beyond the company group

The Radebeul factory is today the largest Koenig & Bauer location and home to three business units: Koenig & Bauer Sheetfed, responsible for the market segments sheetfed offset and post-press equipment (including development, production, sales and service), Koenig & Bauer Industrial as an internal and external production services provider, and Koenig & Bauer Deutschland as the sales and service company for the German, Austrian and Swiss markets.

All three business units are fundamental elements of the overall Koenig & Bauer Group. At the same time, together with our many suppliers and business partners, they form a sound basis for the local and regional labour market in the Upper Elbe valley. With an export ratio of almost 90 per cent, Koenig & Bauer can also point to an international trade performance well ahead of the Saxon and German national averages (36 and 40.7 per cent respectively*).

Employee festivities and other jubilee highlights

The Radebeul location is celebrating its 125th anniversary in numerous ways. On 23 August, Saxon minister-president Michael Kretschmer visited the factory and answered questions from the employees within the framework of an informal ‘barbecue chat’.

On 29 September, a day of special festivities was organised for the employees. Current and former members of the supervisory and executive management boards also attended. The festivities gave the employees an opportunity to experience ‘their’ company in a different light – with a party marquee and activity stalls, with cultural and musical highlights, and with refreshments for every taste. Michael Kretschmer also passed on his congratulations in the form of a video message in which he emphasised: “For me, it is magnificent to see how you have guided a factory location with such great traditions into the future.”

Further events with customers, shareholders, business partners and employees from other group locations are planned for October. Mention must also be made of a richly illustrated commemorative book that offers unusual insights into what goes on behind the scenes in printing press manufacturing and introduces some of the 1,800 employees through a series of gripping stories.

Printing press manufacturing in Saxony (highlights)

1898 Founding of Dresdner Schnellpressenfabrik

1902 Patent obtained for a planetary drive; this was the origin of a new product name and later the name of the company

1924 Merger to form Dresden-Leipziger Schnellpressenfabrik

1932 Planeta Deca: the world’s first four-colour sheetfed offset press

1938 Company name changed to PLANETA Druckmaschinenwerk

1948 Founding of VEB Druckmaschinenwerk Planeta

1952 High-speed press Planeta Super-Tertia

1965 Introduction of the Planeta Variant, the first sheetfed offset press in a unit-based design

1967 Patent registered for a convertible perfecting facility for unit-type presses

1972 Completion of the 42,000 m2 production hall

1986 Delivery of a sheetfed offset press with 10 printing units to the USA

1991 Gradual takeover from Treuhand and integration into the Koenig & Bauer Group

1998 Centenary celebrations

2002 Once-in-a-lifetime Elbe floods threaten the factory site

2008 Rapida 106 declared the makeready world champion after printing 15 jobs of 520 sheets each in 59 minutes and 36 seconds

2016/2018 Following the integration of Iberica and Duran Machinery, print and post-press know-how covers the entire packaging production workflow

2021 First Rapida presses with fully automatic plate logistics

2023 Delivery of the first VariJET 106, a digital inkjet press for the packaging production of the future

*Source: Baden-Württemberg, State Statistical Office; see www.statistik-bw.de/HandelDienstl/Aussenhandel/AH-XP_exportquote.jsp