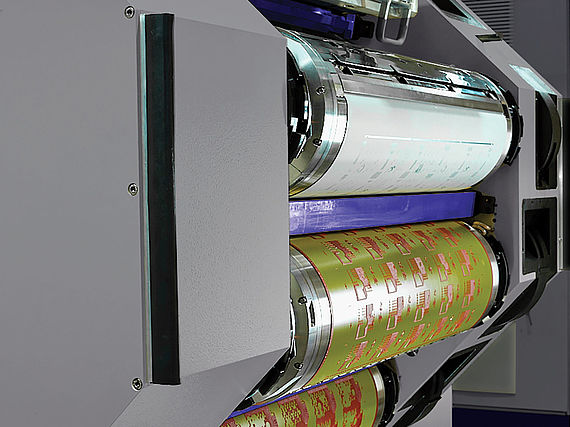

Simultan Offset printing process is a fundamental printing technology used in all banknotes in circulation. Incorporating the finest design elements and Security Features for machine readability (including fluorescence and phosphorescence) acts as a functionally dynamic help for the machine as well as human recognition and authentication.

While Simultan Offset is one of the most cost-effective processes in the banknote production line, we offer smart flexible design, precision and accuracy of the highest standards of quality throughout various processes. The pre-press (design and digital offset platemaking) to the press (plate mounting, plate-blanket interaction, and other mechanical aspects) needs to be controlled and understood to optimise the printing results. We ensure fully integrated workflow and smooth print production throughout the entire process.

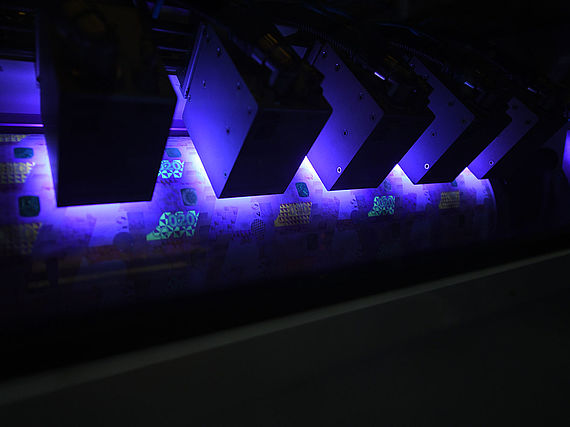

Screen printing offers a wide range of Security Features that need to be secure on multiple levels. They can no longer afford to be only visually striking, they also need to be machine readable and durable.

Varnishes, resins or inks that contain pigments are adapted to the customers' needs and for functional, process stabilising or security purposes. Inks with various physical and chemical properties allow for innovative Security Features which have high levels of longevity even under the most extreme conditions throughout the banknote cash cycle.

Application features are highly effective that create striking effects of movement, depth, and image or colour shifts. Innovative technologies are engineered with nanometric precision and maxmised productivity on multilayers that are difficult to print with conventional printing machines.

Combining processes is also key to enhance security against counterfeiting. The application of any feature can be offered at different stages throughout the banknote production, granting additional dimensions of depth and movement to the banknote.

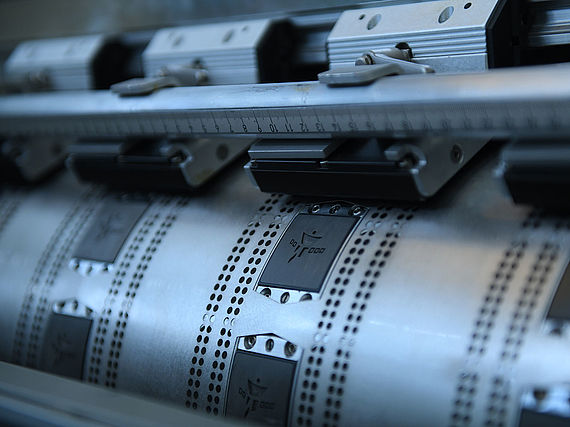

Intaglio is regarded as the cornerstone of banknote security, relied by governments and Central Banks throughout the world. Across the three stages of banknote creation: design, platemaking, and printing, we have been changing the process to be more sustainable and efficient. Once seen as old fashioned, expensive and polluting, Intaglio is capable to be a modern, environmentally friendly and efficient solution for the future.

Our designers and engravers create true innovative security by using powerful applications that improve production efficiency while achieving high-quality work through a simplified process. The data is then transferred to the platemaking thanks to dedicated software that reduces errors to a minimum, hence a reduction of wastes. This philosophy is kept all along the platemaking workflow, leading to a more environmentally friendly process.

Finally, the high pressure of the Intaglio press then allows ink to be transferred into deep engravings on any substrate. This ensures a high level of embossing, guaranteeing that tactile marks efficiently help the blind and visually impaired community.

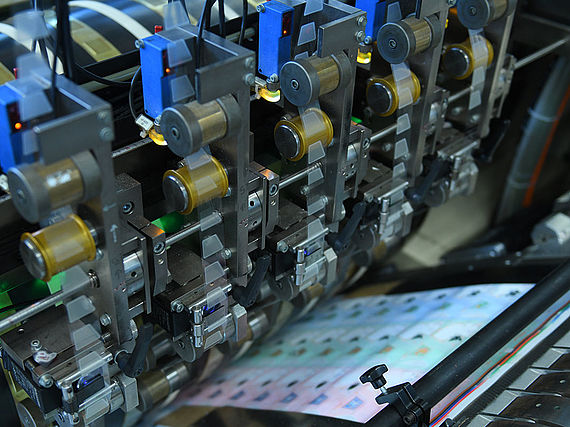

Numbering & Varnishing are key elements for you to lead into your Finishing process.

Numbering systems should be versatile solutions adapting to your cash cycle. Every country needs its own individual cash tracking system for banknotes in circulation. Our Numbering solutions offer you full freedom of choice in terms of sequential or partially sequential numbering. Or go custom: implement any special numbering sequences for replacement or limited editions.

Varnishing both sides of the banknote sheets increases the durability of the banknote while providing better protection against soiling throughout its life cycle. This will prepare you for highly resilient cationic UV-curable varnishes, which ensure low gloss, high transparency, high mechanical strength and provide a unique protective coating for banknotes, while sparing the effects of micro-optical features.

Finishing depends on Numbering and all the previous printing processes which will ensure extreme accuracy for pile preparation, cutting sheets, banding and packing your finished banknotes. Achieve the means to fully automate these processes through the integration of powerful technology in a seamless automated workflow.

Each of our modules can be selected individually to assemble the ideal solution for your requirements. Build the platform you need today, keeping the freedom to upgrade and add new options tomorrow.