One such company is Druckerei Münch in Bayreuth. The family-run business has been producing postcards and greeting cards for more than 60 years and today counts 42 employees. Many of the leading publishing houses in Germany have cards printed here. But it is then the publisher's name which stands on the back of the cards; the printer remains unmentioned.

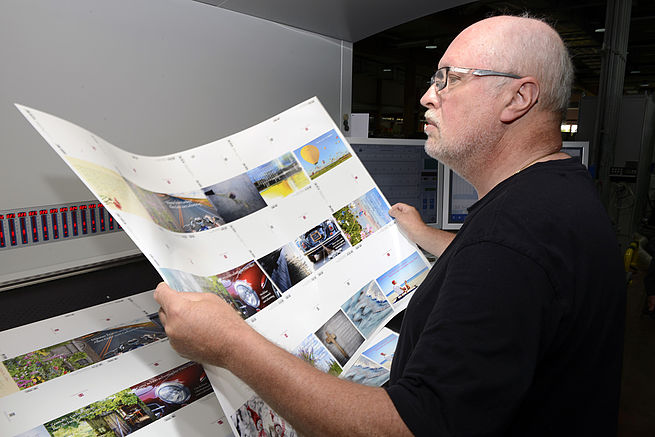

Druckerei Münch has organised its work into gang formes almost from the very beginning. That makes production especially cost-effective. The product spectrum, however, has changed in recent years. The social media boom has led to a decline in the share of postcards. The market for birthday and greeting cards, on the other hand, has developed positively. Card design seems to know no limits. With expensive materials, high-quality coatings, haptic effects and hand-finished details, a card can often be seen as a gift in itself.

Market changes are reflected in press room equipment

The shift in interests on the market has also had consequences in the press room. A 3b press specifically for postcard production, with perfecting after the first unit, is no longer necessary; the available half-format capacity is already sufficient. Instead, manager Uwe Böhner decided to purchase a five-colour Rapida 105 with coater and extended delivery at the beginning of the year. The configuration of this press is geared to the production of greeting cards in batches of between 1,000 and 5,000 cards: Fully automatic FAPC plate changers, CleanTronic washing systems, a fully featured coater for dispersion coatings, direct loading of the pre-press data for press presetting. A non-stop roller rack in the delivery, furthermore, establishes the necessary safe conditions for washing parallel to pile changes.

“There are many features of the high-end Rapidas which we simply don't need,” says Uwe Böhner in explanation of the investment decision. Today, he is certain that it was the right decision: “The press just runs and runs, reliably and trouble-free, day after day.” The VariDryBlue dryers enable further savings by enhancing the efficiency of the energy-intensive drying process.

Sophisticated finishing

The stores are well filled. Standard papers in grammages matched to the post office weight bands, as well as envelopes in the most varied colours and formats, are always in stock. Around 3 million envelopes can be called up at any given time, and publishing house customers are supplied “on demand” from the finished goods warehouse. Some 200,000 to 250,000 cards are shipped every day.

Medium-format sheetfed offset traditionally from KBA

Greeting cards are usually printed with a lead of around six months ahead of the corresponding season or occasion. In other words, summer is the time of the year in which Druckerei Münch takes care of its Christmas and New Year business.

Since discontinuing letterpress printing, Druckerei Münch has relied exclusively on equipment from KBA for its offset printing in medium format. Over the years, the company has invested regularly. An SR III – still using the five-cylinder principle – has been followed by three Rapida 104 and three Rapida 105 models in different configurations. The latest of these presses is based on the same technology platform as the makeready world champion Rapida 106.